How target technology interacts with other areas of work Our mission is:

How target technology interacts with other areas of work Our mission is:

-

To be a ‘one-stop shop’ for accelerator target technology

-

To enable optimum physics performance via sound engineering

Target technology is a limiting factor for many high-power accelerator facilities e.g. for neutron, muon or neutrino production. The Hiigh Power Targets team has built an international reputation in this field and has expertise ranging from concept through to detailed design, prototyping, manufacture, and commissioning.

We can demonstrate our capabilities in solving a wide range of technical challenges and are a partner of choice for new and existing accelerator facilities requiring innovative target technology.

Target Design

We specialise in the design of accelerator beam-intercepting devices.

The T2K target exchange tooling design

Our work involves the design of targets, beam windows, collimators, and dumps. Common challenges include high energy deposition, radiation damage to materials, and the need for remote handling of activated components.

The T2K target exchange tooling design

Our work involves the design of targets, beam windows, collimators, and dumps. Common challenges include high energy deposition, radiation damage to materials, and the need for remote handling of activated components.

We aim to maximise overall system performance as a function of both instantaneous physics performance and engineering reliability. This is not easy! Predicting reliability is difficult and subjective. Factors such as stress, temperature, materials, geometry, environment, change out time and budget can all be important.

We have expertise ranging from conceptual and detailed design, physics and engineering analysis, prototyping, and testing, to specialist manufacturing techniques, including joining dissimilar materials and remote handling.

Target Technology Development

We research and develop new technologies for next-generation facilities.

An induction heating cooling test is performed on a packed bed target arrangement Ongoing improvements in accelerator technology mean that targets have to cope with ever-higher beam powers. To manage the extremely high heat deposition, the target can be split into smaller segments. Solid targets can be replaced with a packed bed of spheres, liquid metal, or even

fluidised powder. We carry out ground-breaking experiments on these emerging technologies, for example:

An induction heating cooling test is performed on a packed bed target arrangement Ongoing improvements in accelerator technology mean that targets have to cope with ever-higher beam powers. To manage the extremely high heat deposition, the target can be split into smaller segments. Solid targets can be replaced with a packed bed of spheres, liquid metal, or even

fluidised powder. We carry out ground-breaking experiments on these emerging technologies, for example: -

Experiments with induction heating and measuring cooling rate through packed beds of spheres

-

Development of a test rig to handle fluidised tungsten powder

-

Investigating the response of tungsten powder to a high-powered proton beam at CERN.

Engineering Simulations

We have expertise in a wide range of engineering and physics simulation software.

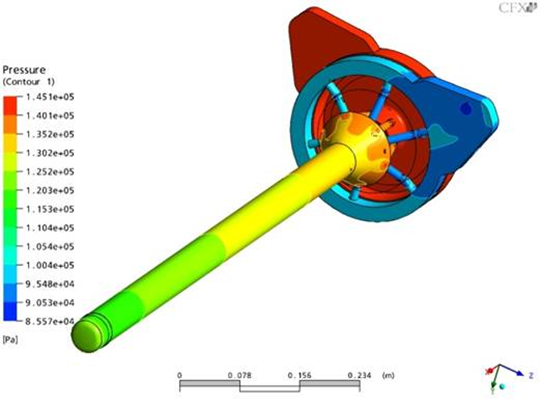

A diagram demonstrating helium flow pressure drop in a T2K targetWe use several simulation packages for areas such as particle transport (FLUKA), Computational Fluid Dynamics (CFX), finite element thermal, structural and multi-physics simulations (ANSYS). We have experience in carrying out many complex, non-standard analysis cases including multi-phase Computational Fluid Dynamics (CFD), stress wave propagation, and transient and fatigue simulations.

A diagram demonstrating helium flow pressure drop in a T2K targetWe use several simulation packages for areas such as particle transport (FLUKA), Computational Fluid Dynamics (CFX), finite element thermal, structural and multi-physics simulations (ANSYS). We have experience in carrying out many complex, non-standard analysis cases including multi-phase Computational Fluid Dynamics (CFD), stress wave propagation, and transient and fatigue simulations.

Having all this expertise in one place allows us to design and optimise all aspects of target performance.

Multiphysics Integration

We are adept at moving data between different simulation environments to get insights into the complexities of load conditions in acceleration beamlines.

A finite element model of a magnetic horn Accelerator beamline components may be subject to a complex array of load conditions under operation. For example, there are a range of thermal, mechanical, and electromagnetic loads acting over a diverse range of timescales. Our ability to exchange data between multiple simulation environments to determine how these loads interact is a key enabling factor in our engineering assurance work.

A finite element model of a magnetic horn Accelerator beamline components may be subject to a complex array of load conditions under operation. For example, there are a range of thermal, mechanical, and electromagnetic loads acting over a diverse range of timescales. Our ability to exchange data between multiple simulation environments to determine how these loads interact is a key enabling factor in our engineering assurance work.

Target Materials Research

We know a great deal about existing materials for accelerator target work and carry out our research with international collaborators.

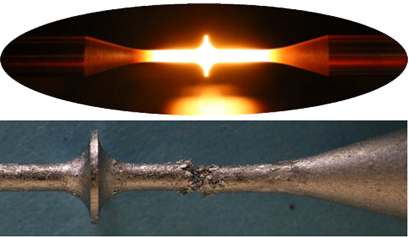

A high-temperature thermal fatigue test of tungsten, during (above) and after (below)Accelerator target applications often involve exotic materials and extreme conditions, such as very high temperatures, strain rates, and radiation doses. We have a broad knowledge of the existing materials data, and where this is not enough, we carry out our own materials research and collaborate with international accelerators and materials science experts.

A high-temperature thermal fatigue test of tungsten, during (above) and after (below)Accelerator target applications often involve exotic materials and extreme conditions, such as very high temperatures, strain rates, and radiation doses. We have a broad knowledge of the existing materials data, and where this is not enough, we carry out our own materials research and collaborate with international accelerators and materials science experts.

For example:

Fatigue testing of tungsten at high temperature and strain rate

Testing of titanium foils irradiated at BLIP facility, Brookhaven National Lab

Thermal fatigue testing of metal-ceramic joints

We are also a founding member of the

RaDIATE collaboration, which was set up to address the lack of relevant data on high-energy proton radiation damage effects in common target and beam window materials.

RaDIATE Collaboration

The RaDIATE Collaboration seeks to connect the accelerator community with those working in other fission and fusion fields to share experiences and create new ideas.

JPARC and CERN signing the RaDIATE memorandum of understanding in 2017

RaDIATE (Radiation Damage In Accelerator Target Environments) is an international collaboration which aims to:

JPARC and CERN signing the RaDIATE memorandum of understanding in 2017

RaDIATE (Radiation Damage In Accelerator Target Environments) is an international collaboration which aims to:

-

Introduce materials scientists, with expertise in radiation damage, to the accelerator target community

-

Apply joint expertise to target and beam window issues

-

Co-ordinate in-beam experiments and post-irradiation examination

The collaboration has identified materials of particular interest to members and guides research on the properties of those materials in various irradiation regimes and with other physical environmental factors - such as temperature, dose rate, duty factor, and dynamic stress. Programmes of work are devised and carried out, and results are reported to the rest of the members, and then further work is planned.

Networking together across the traditional physics and engineering disciplines allows for new insights and synergies to be established, and further work planned to address emerging issues that members identify.

To read more about the RaDIATE Collaboration and its 13 member institutes, visit

their website.

Advanced Target Manufacturing Techniques

We have gained experience and expertise in manufacturing techniques for targets used in high-radiation environments.

The wire electro-discharge machining of a tungsten sample Our manufacturing techniques include:

The wire electro-discharge machining of a tungsten sample Our manufacturing techniques include:

-

Vacuum brazing of metals, ceramics, and graphite

-

Electron beam and TIG (tungsten inert gas) welding

-

Machining of exotic materials (e.g. Tungsten, Titanium alloy, graphite, etc)

-

Stress relieving and heat treatment of reactive metals

-

Hot Isostatic Pressing (HIP) and diffusion bonding

-

Target alignment and metrology

-

Precision pipe bending of thin wall tube

-

Quality assurance

-

Helium leak testing

-

Pressure testing

Target Assembly and Commissioning

We can deliver complete target assemblies and provide the customer with ongoing maintenance and support.

A metrology inspection of the NoVa Neutrino Target

We have a great deal of experience in precision assembly, quality assurance, helping the customer with installation/commissioning, and providing ongoing operational support. For example, we have delivered target systems to

Fermilab

(USA) and

T2K

(Japan) both of which have operated successfully. We provide ongoing maintenance and operation support for the T2K system.

A metrology inspection of the NoVa Neutrino Target

We have a great deal of experience in precision assembly, quality assurance, helping the customer with installation/commissioning, and providing ongoing operational support. For example, we have delivered target systems to

Fermilab

(USA) and

T2K

(Japan) both of which have operated successfully. We provide ongoing maintenance and operation support for the T2K system.

We carry out Quality Assurance activities to meet customer requirements including design calculations, material qualification/testing, dimensional metrology (coordinate measuring machine), alignment, non-destructive testing (NDT) weld qualification, helium leak testing, coolant flow, and thermal testing. We routinely travel to customer sites to carry out commissioning and maintenance activities.

Remote Handling

Through careful design, we enable safe and effective remote handling of radioactive components.

The T2K-target-remote exchanger system

The T2K-target-remote exchanger system

We have experience in designing targets and supports for remote handling, as well as designing target remote exchange equipment. As accelerators are becoming increasingly powerful, remote handling has become an essential part of high-power target design to enable targets to be exchanged safely. We have also designed remote-handling equipment to carry out unplanned repair tasks on the T2K helium pipes.

As a result of operating in a high-power accelerated particle beam, our components become highly radioactive, making hands-on repairs or replacements impossible. Instead, these components must be handled remotely, using robotic or human-controlled manipulator arms, lead glass windows, and radiation-hard cameras. This can make simple maintenance operations much more challenging, so the need for remote handling must be considered throughout the design process.

Programme Highlights

We are a partner of choice in many new accelerator facilities requiring high-power target technology. The objective is optimum physics performance via reliable engineering.

Our recent programme includes:

Find out more about our programme highlightts by reading Technology's project showcase.

Contact us

For enquiries regarding target design and manufacturing, please contact Chris Densham.