As accelerator technology continues to develop, there is a demand for targets that can accommodate higher beam powers and more focused beam pulses. This causes a range of target issues including high thermal stress, high radiation damage, and high residual heat when the beam is switched off. Stationary solid targets cannot survive under these conditions, so a rotating target wheel or a flowing liquid mercury target is typically used instead. However, rotating solid targets are still vulnerable to breaking and liquid mercury targets are prone to cavitation damage, so even these cannot cope with extremely high power and highly focused pulsed beams.

We proposed fluidised tungsten as an alternative solution which could avoid many of the problems of these alternatives, providing a reliable target technology for the most demanding high-power applications. A long-running programme of research and development is underway to demonstrate the feasibility of this new technology. This research is split into two key areas; showing that tungsten powder can be handled using available technology, and understanding how the powder behaves when shot with a proton beam. We have published several peer-reviewed articles based on this research.

The fluidised powder handling rig at Rutherford Appleton Laboratory, showing key components of the cycle: 1. Pressurised powder hopper, 2. Ejection of dense phase powder (proton beam would intercept here), 3. Suction lift of lean phase powder, 4. Gravity chute refills powder hopper.

The fluidised powder handling rig at Rutherford Appleton Laboratory, showing key components of the cycle: 1. Pressurised powder hopper, 2. Ejection of dense phase powder (proton beam would intercept here), 3. Suction lift of lean phase powder, 4. Gravity chute refills powder hopper.

.

Powder Handling Rig

Fluidised powders are routinely handled in industry, for example moving flour around a cake factory or coal dust around a power plant. However, tungsten is many times denser than any material that had previously been fluidised, so a custom test rig was built at Rutherford Appleton Laboratory. The rig has been developed over many years, and has successfully demonstrated the key powder handling processes required for a real target facility; the powder can be ejected in a dense phase suitable for a target, lifted in a lean phase, and then dropped back to the starting point under gravity. Managing erosion due to the powder is challenging, but we are implementing methods to measure and reduce this. Since undertaking this work, other organisations have investigated similar technologies for processing dense materials, such as nuclear fuels.

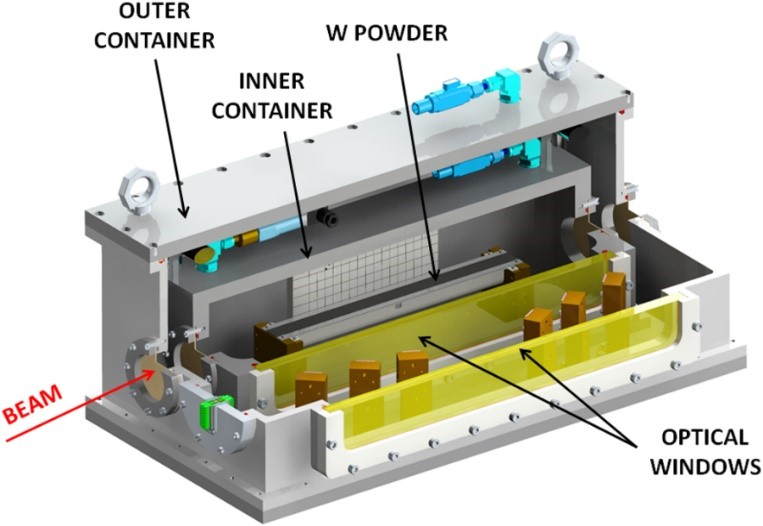

Experiment setup for tungsten (W) powerder in-beam testing at CERN

.

In-Beam Testing

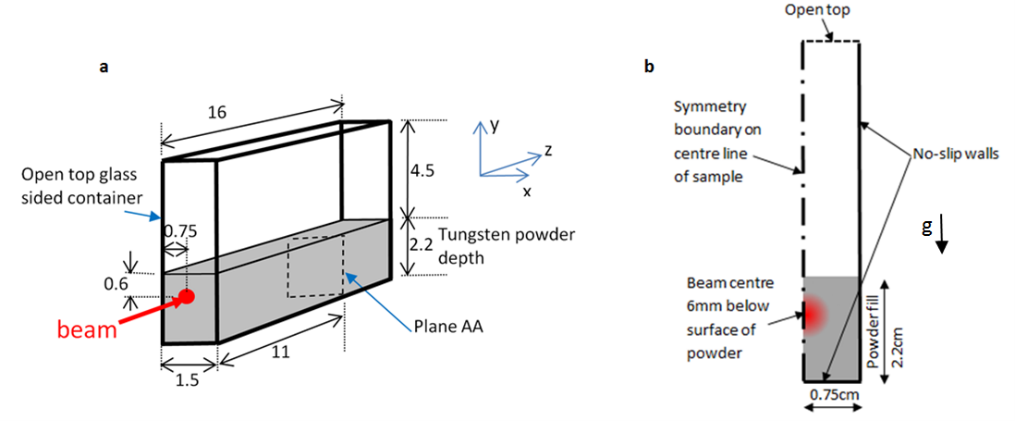

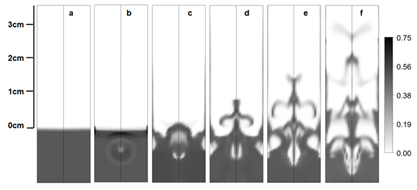

The response of powdered tungsten to a proton beam passing through was investigated at the HiRadMat facility at CERN. We designed and built an experiment that allowed a proton beam to pass through an open-topped trough of tungsten powder while keeping the powder safely contained. The response of the powder was filmed using a high-speed camera and the force on the trough was measured using a laser Doppler vibrometer. The beam caused the powder to be ejected from the trough. However, the powder is ejected much less violently than liquid mercury under the same conditions, implying that a powder target should be easier to contain than a liquid mercury target under the same conditions.

We believe the observed disruption of the tungsten powder can be explained by a coulombic eruption of the tungsten particles. The high-energy beam pulse leaves a pattern of charge distributed in the poorly conducting powder sample, which creates an electric field that consequently results in a force acting on the individual charged particles. We have used a combination of FLUKA and multi-phase CFD modelling to calculate the charge deposited on the tungsten powder, the electric field and the resulting acceleration showing that this is a plausible mechanism for causing the observed eruptions.

(Left) Plan of the open-topped box filled with tungsten powder used in the experiment. (Right) Plan used during computation - right half of a cross-section of the box showing initial powder and boundary conditions, and the position of the proton beam (symmetry assumed)

.

.

Publications

Fluidised powder handling:

-

C.J. Densham, O.Caretta and P.Loveridge, “The potential of fluidised powder target technology in high power accelerator facilities,” in Proceedings of PAC09, WE1GRC04, Vancouver, BC, Canada, 2009.

-

T. Davies, O. Caretta, C. Densham and R. Woods, “The production and anatomy of a tungsten powder jet,” Powder Technology, vol. 201, no. 3, pp. 296-300, 2010. DOI: 10.1016/j.powtec.2010.03.018

In-beam testing:

-

O. Caretta, T. Davenne et al., “Response of a tungsten powder target to an incident high energy proton beam,” Physical review special topics - accelerators and beams, p.DOI: 10.1103/PhysRevSTAB.17.101005, 08 2014.

-

O.Caretta, P.Loveridge et al., “Proton beam induced dynamics of tungsten granules,” Physical Review Accelerators and Beams, vol. 21, March 2018. DOI: https://doi.org/10.1103/PhysRevAccelBeams.21.033401

Written by Chris Densham and Dan Wilcox, High Powered Targets group leader and team member respectively.