The T2K experiment began in 2008. It sends the world’s most intense neutrino beam from the J-PARC facility at Tokai (in the east of Japan) 295 km through the earth to the Super Kamiokande neutrino detector (in the west of the country), with the aim of studying the properties of these tiny, weakly interacting particles.

We are responsible for the

-

Neutrino production target

-

Target exchange mechanism

-

Vacuum-to-air beam window

-

Collimator/baffle

-

Hadron absorber

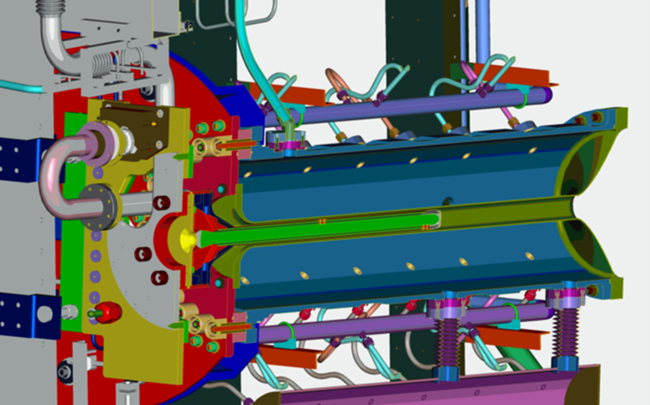

Neutrino Production Target

We are responsible for the T2K neutrino production target which converts the high-power proton beam into neutrinos. It is a 1-metre0long graphite rod encased in a titanium container cooled with helium. We designed and optimised the target for mechanical and thermal stresses using ANSYS Finite Element Analysis (FEA) code and the flow using ANSYS CFX Computational Fluid Dynamics (CFD). The target is designed to cope with a proton beam power of 750kW and work is currently underway to upgrade it so the power can be increased to 1.3MW.

Cross-section of the T2K target installed in magnetic horn

Cross-section of the T2K target installed in magnetic horn

Target exchange mechanism

We designed and developed a remote exchange system that permits highly radioactive failed targets to be safely and quickly replaced using master-slave manipulators in a remote maintenance area. This allows the large and expensive magnetic horn in which the target is installed to be reused saving money and reducing radioactive waste. This is a challenging task as the clearance between the target and horn bore is only 3mm and the target is 1 metre long and contains delicate graphite components.

T2K Target remote exchanger system

Vacuum-to-air beam window

The T2K beam window separates the accelerator vacuum from the target station helium volume at atmospheric pressure. The window consists of two thin partially spherical domes of titanium alloy cooled by helium to remove the heat generated by the passage of the proton beam. It is remotely replaceable and seals mirror flanges using inflatable metal seals.

The T2K window assembly: in the centre of the assembly, a hemispherical structure can be seen which is the thin titanium beam window. Around the window is the inflatable metal seal which consists of two mirror-polished foils connected to metal bellows .

The T2K window assembly: in the centre of the assembly, a hemispherical structure can be seen which is the thin titanium beam window. Around the window is the inflatable metal seal which consists of two mirror-polished foils connected to metal bellows .

.

A Computational Fluid Dynamics (CFD) plot showing helium streamlines between the titanium domes

Collimator/baffle

The T2K baffle/collimator is situated between the beam window and the target. The main functions of this component are:

-

To protect the target, magnetic horns and hadron absorber from damage due to a mis-steered proton beam;

-

To reduce activation and damage of components upstream of the target.

The core of the baffle consists of a large block of graphite. The graphite block has a 30mm bore for the proton beam to pass through under normal conditions. To protect the graphite and reduce future radiological contamination, the graphite is clad in zinc-coated steel plates. The baffle incorporates thick steel shielding blocks thatfit into the target station shielding to create a labyrinth seal and reduce radiation backscattering from the target to the final focusing section magnets. To keep the assembly cool during operation it has cooling pipes embedded in the outer edges of the graphite.

The T2K collimator/baffle: (Left) The graphite core can be seen where the engineer is making an adjustment. (Right) CAD design of the T2K collimator/baffle.

The T2K collimator/baffle: (Left) The graphite core can be seen where the engineer is making an adjustment. (Right) CAD design of the T2K collimator/baffle.

.

Hadron absorber

The hadron absorber is a large assembly of graphite blocks that must absorb the remnant hadrons some 100 metres downstream of the production target. It is cooled by aluminium cooling modules connected to the ends of the graphite block. The hadron absorber is not replaceable or upgradable so it has been designed to cope with 3MW beam power.

(Left]) Finite Element Analysis (FEA) plot of the hadron absorber assembly showing deflections due to thermal expansion. (Right) Engineer standing in front of the hadron absorber during construction. The hadron absorber consists of segmental graphite blocks with cooler modules on the sides. The size of the assembly is 2.3 metres wide and 4.7 metres tall.

.

Written by Chris Densham and Mike Fitton,

High Powered Targets' group leader and team member respectively.