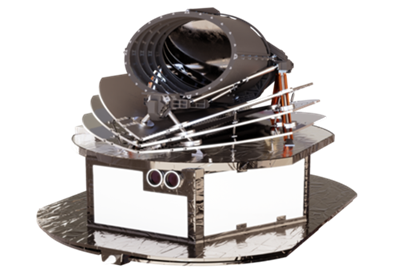

Ariel Spacecraft (image credit: Airbus)Ariel is the adopted M4 (medium class) mission within the

ESA Cosmic Vision programme. Its objective is to study exoplanets, specifically their atmospheric chemical composition and thermal structure. The scientific payload comprises two instruments: a Fine Guidance System (FGS) and the Ariel Infrared Spectrometer (AIRS).

Ariel Spacecraft (image credit: Airbus)Ariel is the adopted M4 (medium class) mission within the

ESA Cosmic Vision programme. Its objective is to study exoplanets, specifically their atmospheric chemical composition and thermal structure. The scientific payload comprises two instruments: a Fine Guidance System (FGS) and the Ariel Infrared Spectrometer (AIRS).

The Ariel Telescope Optical Bench, upon which AIRS and the FGS instruments are located is passively cooled to 50–55 Kelvin through heat radiators coupled to deep space. However, the two AIRS detector channels must be cooled to around 40 Kelvin to operate correctly, requiring an additional Active Cooler System (ACS) to achieve this.

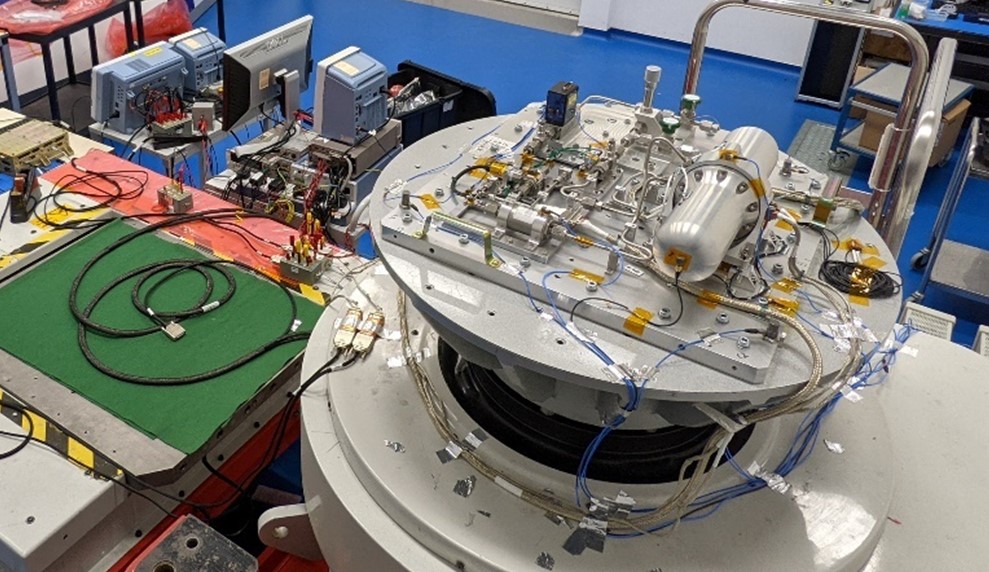

The Cryogenics and Magnetics group are providing the ACS for the Ariel mission, with the control electronics being supplied by OHB System AG. The ACS is a closed-cycle Joule-Thomson mechanical cryocooler using neon as the working fluid. This will be the first time that a Neon JT-Cooler will have been flown in space and significant development activities are being carried out to mitigate the risks associated with this fluid, including its very high sensitivity to contamination and the operating regime dictated by its thermophysical properties.

As part of that development, we have designed, manufactured, and tested a Demonstration Model cooler. The suite of performance tests included vibration, shock, and thermal cycling to simulate the Ariane 62 launcher's mechanical and thermal environmental loads, cryogenic performance tests under thermal vacuum conditions to demonstrate the cooling power capability under expected in-orbit conditions.

The mechanical cooler utilises an active vibration control system to reduce the exported vibrations as low as possible, since these may cause jitter, affecting the telescope performance, so residual micro-vibration characterisation tests have also been carried out on the technology demonstration cooler.

The Ariel demonstration model cooler undergoing launch vibration testingSensitivity of the Neon working fluid to contamination, particularly nitrogen, is a concern as this could cause a blockage at the cooler cold tip where there is a very small orifice. A gas scrubbing rig is in development and a proof of concept has been manufactured and was used to purify the Neon for the DM cooler, reducing the calculated nitrogen contamination to less than 50 ppb.

The Ariel demonstration model cooler undergoing launch vibration testingSensitivity of the Neon working fluid to contamination, particularly nitrogen, is a concern as this could cause a blockage at the cooler cold tip where there is a very small orifice. A gas scrubbing rig is in development and a proof of concept has been manufactured and was used to purify the Neon for the DM cooler, reducing the calculated nitrogen contamination to less than 50 ppb.

The Demonstration Model cooler has met all of the performance requirements within the allocated resource budgets (such as mass, size and power) and the ACS development has passed the Preliminary Design Review. The next step is to produce a Qualification Model cooler that will first be tested at the cooler sub-system level before integration into the Ariel Engineering Model Payload Module for subsequent system-level tests.

Written by Martin Crook, Cryogenics and Magnetics group leader.