Muon imaging can reveal hidden structures deep beneath the Earth’s surface using particles that rain down from space. While this may sound like science fiction, this technology is very real.

We partnered with geoscience start-up Geoptic on the latest phase of their pioneering borehole imaging system, making this technology more accessible to industry, from geological surveys to civil engineering.

From Ancient Tombs to the Swiss Alps

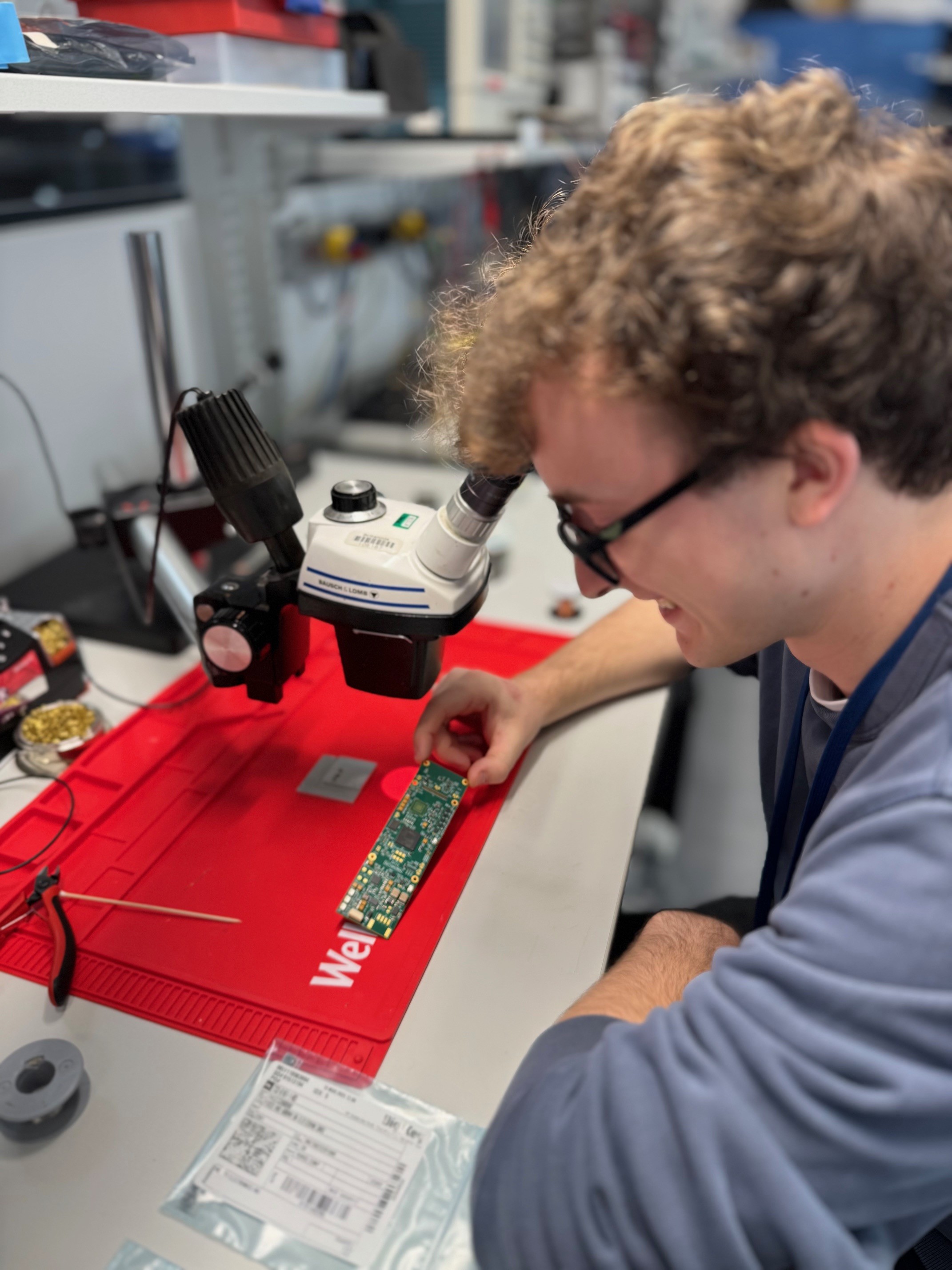

Dan Gorman inspects the new data acquisition PCBMuon imaging, also called muography, harnesses naturally occurring radiation from cosmic rays to create a picture of the Earth’s density and composition.

Dan Gorman inspects the new data acquisition PCBMuon imaging, also called muography, harnesses naturally occurring radiation from cosmic rays to create a picture of the Earth’s density and composition.

Muons are produced when cosmic rays collide with the atomic nuclei in the atmosphere. When these particles eventually fall to Earth, the denser the material that they collide with, the more muons are absorbed.

By using detectors to capture the particles that aren’t absorbed, researchers can create an accurate image of hidden structures without directly disturbing the area being studied.

This technique has already facilitated remarkable breakthroughs. In 2023, it revealed a hidden corridor in the Great Pyramid of Giza and, between 2015 and 2019, helped scientists map the shape of bedrock beneath glaciers in the Swiss Alps.

Geoptic, a university spin-out and leader in muon imaging, has developed a borehole system using this technique.

First tested at STFC’s Boulby Underground Laboratory, their technology can be lowered into boreholes of up to 1.5 km deep and was recently deployed in Norway to monitor carbon capture and storage processes.

In 2024, Geoptic received a grant award from UKRI’s Industry Impact Fund (I2F) to collaborate with the Technology Department on advancing its detectors for applications in mining, civil engineering, and beyond.

Designing for Extreme Conditions

As a result of this successful partnership, our team designed a system capable of reading out up to 64 channels of silicon photomultipliers, significantly improving the detector’s muon tracking resolution.

The final circuit board measures only 4 cm x 14 cm, making it significantly smaller than our typical readout systems and reducing the size of the borehole electronics by half.

With an internal diameter of only 5.4 cm, the housing represents just one of the constraints posed by the detector. The instrument must also operate at depths of 1.5 km.

Temperatures underground increase along a geothermal gradient, which differs depending on the location. In the UK, for example, the Earth’s temperature increases by an average of 27 °C per kilometre.

Geoptic’s system, however, is designed to withstand thermal gradients of up to 40 °C per kilometre, making it suitable for use in harsh environments worldwide.

Despite these challenges, this project progressed extremely rapidly, moving from launch to delivery in only nine months.

Building on World-Class Expertise

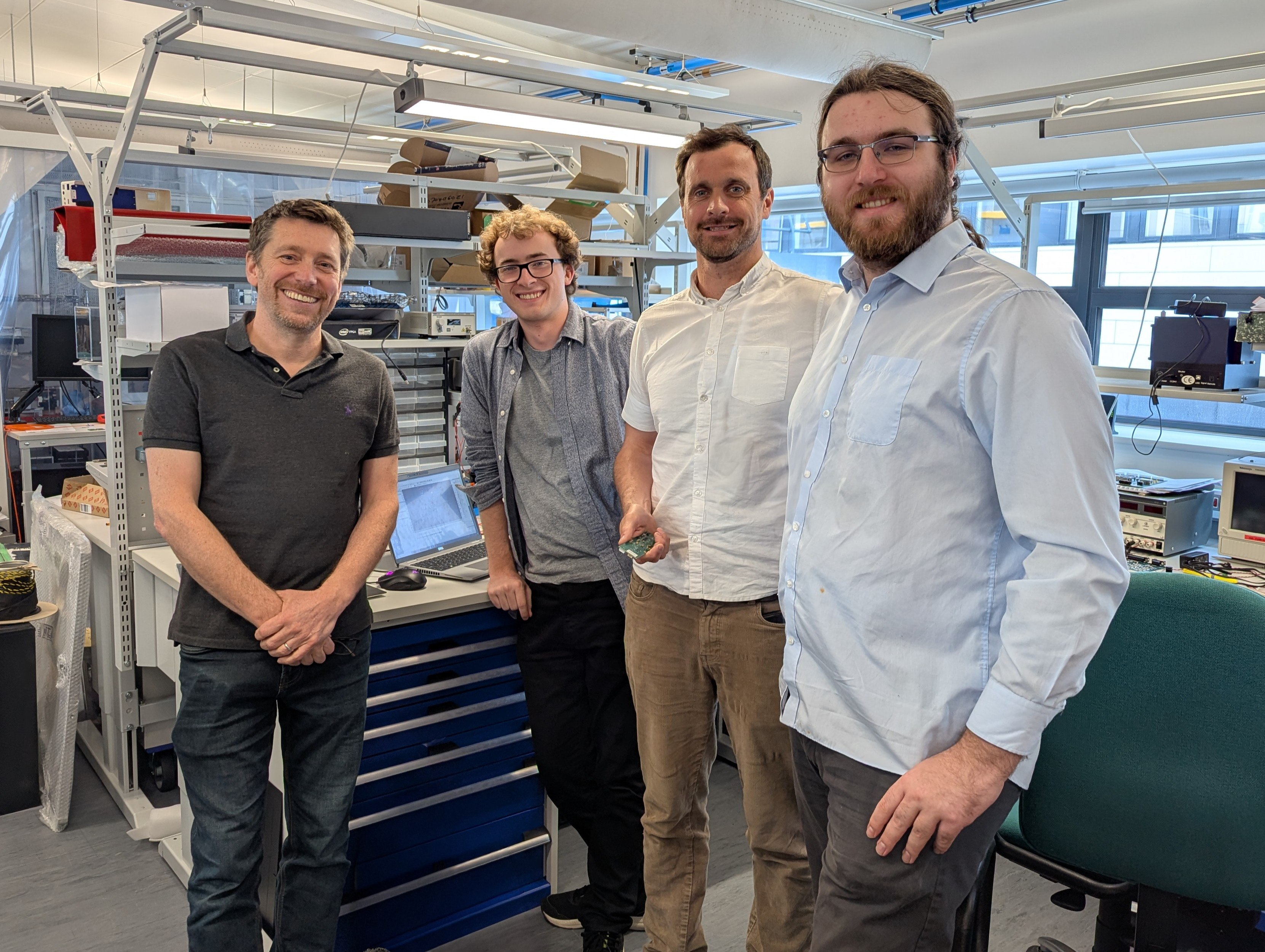

Craig Macwaters and Dan Gorman hand the project over

to Geoptic's team

Our team included project lead Craig Macwaters and designer Dan Gorman. The pair are part of our Detector and Electronics Division, which houses detector expertise from microelectronics design through to assembly and packaging services.

A recent project has seen them apply their knowledge to CERN's ATLAS upgrade, producing staves and stave sensors that will eventually be installed into the experiment's inner tracking detector.

When asked about their work with Geoptic, Dan, an electronic systems engineer, shared:

“The project was an unusual challenge for the borehole electronics team – it came with a number of difficult constraints such as extreme space and temperature requirements, all while providing a drastic increase in performance. It was an interesting insight into commercial cost engineering and optimisation for large-scale manufacturing. It was a pleasure to work with the Geoptic team and learn about their industry.”

Dr Chris Steer, Geoptic’s Managing Director, added:

“With STFC’s strong pedigree in detector electronics design, the project was set for success from the start. The STFC team worked closely with [our] engineers to explore novel design options for the new electronics board, leading to an implementation that fully met the ruggedised instrument’s deployment requirements with a very effective design.”

The partnership facilitated by UKRI's I2F grant enabled Geoptic to access advanced electronics design capabilities that would have been otherwise out of reach and clearly demonstrates how particle physics expertise has practical, commercial applications.

Written by Cat Lewin-Williams.