The ATLAS endcap during assembly

Although the Project and Mechanical Engineering (PME) team's roots began in the production of experimental equipment for particle physics, over the last 15 years we have worked hard to diversify and now deliver work for a wide range of scientific disciplines.

The ATLAS endcap during assembly

Although the Project and Mechanical Engineering (PME) team's roots began in the production of experimental equipment for particle physics, over the last 15 years we have worked hard to diversify and now deliver work for a wide range of scientific disciplines.

We provide fully engineered solutions which draw upon their wide-ranging engineering skills and all of our work is completed within an

ISO 9001 framework. We work hard to share our knowledge with all the disciplines we work with and are always looking for opportunities to bring our knowledge to new areas of science.

When working on projects, we start with a customer’s concept which we develop with the customer into a full specification. From this, we engineer, deliver and commission complete systems. It is not always clear at the outset what the challenges will be during a project, and we often draw in specialist skills from across STFC to form a complete project team.

To find out more about our PME capabilities, read our Engineering Case Studies.

Skills

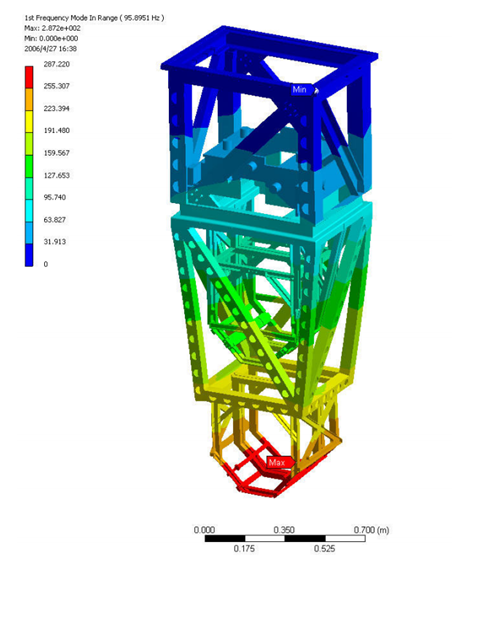

Finite Element Analysis

An aerial view of Rutherford Appleton Laboratory We are experienced in many areas of FEA including fluid dynamics, modal static, time history, composite materials, thermal, and stress and deformation linear studies. While a great deal of engineering can be based upon experience and basic engineering theory, a large amount of what we do needs to be optimised to push the technology to its limits. For this we use a range of analysis tools - ANSYS is our preferred FEA solver but we also use ABAQUS, FEMAP, and Mechanica.

An aerial view of Rutherford Appleton Laboratory We are experienced in many areas of FEA including fluid dynamics, modal static, time history, composite materials, thermal, and stress and deformation linear studies. While a great deal of engineering can be based upon experience and basic engineering theory, a large amount of what we do needs to be optimised to push the technology to its limits. For this we use a range of analysis tools - ANSYS is our preferred FEA solver but we also use ABAQUS, FEMAP, and Mechanica.

Cryogenic Engineering

We are experienced in designing and building cryogenic assemblies. Working on the wide range of projects that we do, we need to have an equally wide range of technical skills to ensure that we can efficiently engineer big science. We are particularly knowledgeable in the following fields:

-

Wet and dry cryostats, often for magnets, but also for other cold applications.

-

Coolers and direct cryogenic cooling.

-

Vacuum technology and how manufacturing methods and pumping influence the absolute pressures attainable.

-

MLI (Multi-Layer Insulation) and understanding how that influences radiative heat losses

-

Calculating heat paths/rates and budgets for cryogenic systems

-

Working in the region of 4K coolers, occasionally colder

Vacuum Technology

The satellite vacuum test chamber being inspected before transport to National Space Test Facility (NSTF) at RAL

The satellite vacuum test chamber being inspected before transport to National Space Test Facility (NSTF) at RAL

We are knowledgeable in designing and building vacuum systems and working with ultra-high vacuums and assemblies for 'in vacuum' operations. We are familiar with designing vacuum systems, such as beamlines and cryostats, and with working on Ultra High Vacuum (UHV). We understand vacuum cleaning and the requirement to bake out before use.

Pressure Vessels ![]()

![]()

![]()

Much of what we design contains some pressure-handling parts. We are experienced in the design and arranging of the manufacture and certification of pressure vessels for many room-temperature and cryogenic applications. We have also designed and built pressure vessels from unusual materials, such as low-radioactivity titanium.

CAD and Drafting

A CAD design for a planar undulator magnet assembly

A CAD design for a planar undulator magnet assembly

Computer-aided design is central to all the work we do. We use CAD throughout the project lifecycle from concept models to detailed drawings or 'direct from CAD manufacture. One role we regularly adopt on projects is large assembly management and integration planning; this necessitates managing very large CAD models and taking responsibility for keeping them up to date and ensuring they maintain compatibility. We do this in either CREO or SolidEdge, depending on the project's needs.

Every year, we produce hundreds of manufacturing drawings for all our projects. These range from the very simple to the extremely complex and high-value. All are independently checked for fit, form and function, and in many cases, are extensively geometrically toleranced to minimise any errors due to ambiguity in the manufacture of parts.

We also have close relationships with several contract engineers who provide CAD services. We directly manage any work they do, taking responsibility for their outputs and integrating their work back into the projects.

Contact us

For enquiries regarding Projects and Mechanical Engineering, please contact group leader Ian Wilmut.